This process is often used for medals and medallions, although it can be used for badges and key rings too. The item is made with a Zinc alloy injected under great pressure into a mould. Although the set up costs are a little higher this is more economical in volume than Die struck designs. This process also overcomes the size limitations of Die struck products - we can use this process for products up to a massive 150mm size. Products can be 2D or full 3D as required with colour fill, all plates and epoxy as you require.

Our Products

Metal

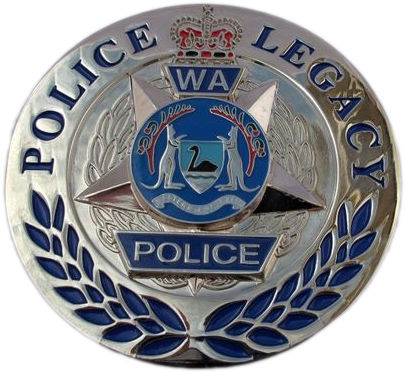

- Steel Based soft enamel

- Brass based soft enamel

- Photo etched soft enamel

- Photo Printed Designs

- Imitation Hard Enamel (Epola)

- 3D Die Struck

- Awards

- Schools

- Car / Car Clubs

- Cuff Links

- Injection moulded

- Key Rings

- Coins

- Medals

- Special Medals

- Sports Medals

- Special

- Plaque Engraving

Name Bars

PVC

Cloth

Contact Details

M & L Australasia Pty LtdPO Box 5015, Centrepoint LPO, Midland

Western Australia 6056

Ph: 0448 284 555

SEARCH

Use keywords to find products or brands.

MY ACCOUNT

Here you can find all orders you have placed online

JOIN OUR NEWSLETTER

Win A Prize

Join Our Newsletter and go into draw for a $200 voucher.

Enter here

Enter here